Step To It

Words - Tajinder Hayer

Photography - Alexander Courtman

Design - Josh Bristow

The Rakish Gent travels to Germany to see how an established fashion brand is doing sustainability well

The small German town of Schmallenberg, around 116km from Cologne, its closest real city, is a quiet and calm location which serves as the headquarters for FALKE. Since its beginnings in 1895, the family business has excelled in producing basics in high-quality materials, finished with handcrafted perfection. With products in all five continents and in over 60 countries, quality has always been at the forefront of the brand’s ethos and perhaps a reason as to how they have stood the test of time.

The business traces its beginnings to roofer Franz Falke-Rohen, who worked as a seasonal knitter in the cold winter months and founded his own knitting mill. The headquarters were opened in 1920 and acquisitions followed. Rapid expansion came after sons Paul and Franz-Otto Falke took over the business and concentrated on exporting and setting up production plans and sales offices in Europe.

Whilst sustainable production has only recently become an integral part of the fashion conversation, for FALKE it has been integral for decades. 1994 saw them receive the German environmental protection award in the category “Environmentally-friendly Products” from BDI (Federation of the German Industry), awarded for the development of “Clima Wool”, an insulating material made of sheep’s wool.

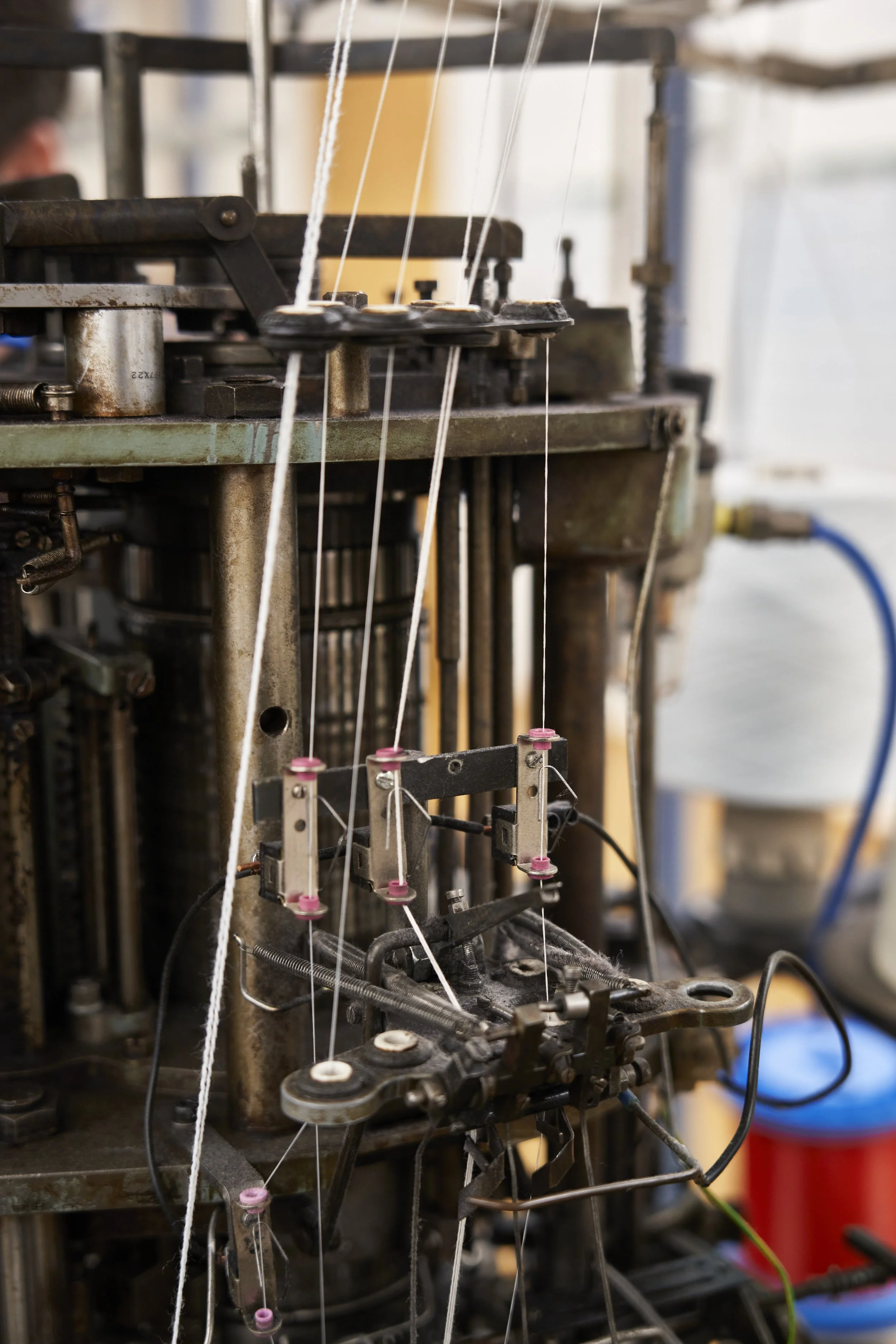

Fast forward to 2023, the FALKE are without question, best known for their socks. This fact is not lost on Kristina Falke. Married to Paul Falke who took over the management of the business with Franz-Peter Falke in 1990, she is the International PR Director for the label. For her “the secret is in the quality and the craftsmanship”. Socks for men, women and children are still performing well and Kristina tells us that “we are number one in the world”. Huge fashion brands are often knocking at the door for their help. When Covid-19 struck, socks for staying at home came a firm favourite across Europe. For anyone that has tried them, they are full of unique details that make them stand apart from competitors with ergonomically designed features and quality fabrics are sourced from global selected yarn suppliers. FALKE set the highest standards of quality with the Luxury Line of the Men's Legwear collection. Only the best yarns, such as mercerised merino, silk and cashmere are used to create a wide palette of bold, intense colour shades. Perhaps the best example of this (and the lengths that FALKE will go to) are the rare Vicuña range. The fine, dense wool was valued as the rarest and most expensive in the world. After the traditional shearing, the soft and incredibly fine wool hairs of the fleece are carefully freed from the coarser guard hairs and submitted to an elaborate hand-washing and drying process. The final step is to spin the velvety, wafer-thin yarns, which still retain their regal grace and elegance. They are sold by order only and to the cost of around £600. For a single pair of socks. Another example of the efforts that the brand go to to ensure that the wool is the best it can be is the time spent in Australia by four employees who travelled the length and breadth of the country sourcing consciously produced Merino wool. Mulesing (a painful treatment to sheep to prevent infestation of special maggots) identified initially in Australia, led to FALKE undertaking this exercise and subsequently excluding the purchase of wool obtained using this method.

You’d be much better off with a pair of socks from the Luxury Line where prices range from around €35.00+. Kristina fully appreciates that “we are not the cheapest around, but our prices are not so expensive that customers are intimated like they would be by a luxury fashion brand”. FALKE presently have production plants in Germany, Serbia and South Africa, and being able to control the look and feel of the pieces, as well as ensure that employees are treated and paid well are integral to how the business operates. Producing in Europe is a costly exercise and “I’m sure that there are many companies that produce in the Far East that have made a lot more money in the short-term. I think owning your own plants, controlling them, being able to ship easily are all very important.”

Quality and brand loyalty has meant that customers have been coming back for years. To attract new customers, Kristina is of the view “that we have to become a bit younger”. Collaborations are a great way of doing this and help to bring the brand to a new audience. FALKE have been a constant fixture of London Fashion Week for years, helping designers like Daniel W Fletcher, Erdem, Richard Quinn and Molly Goddard bring their unique ideas to life.

How to be sustainable and how to produce better have been high on the agenda for FALKE (and for many German fashion brands). The steps for the next few years cross all different areas of the business. FALKE are currently working on creating their own cotton and tests are going well. In Schmallenberg, laboratories investigate the requirements of physical characteristics and colourfastness to ensure that the limits of certain substances are not exceeded. Production and logistic processes are continuously reviewed to reduce energy consumption, waste and rejects. Beside prevention of pollution and carbon dioxide emission, animal welfare has been integral. Wool is one of the most commonly used raw materials for the brand and so, animal protection has been set as an essential principle in the FALKE Quality Guideline. Whilst certain distributors insist on having products packed in plastic for protection of the product, FALKE are striving to abandon plastic packaging entirely. The FALKE Ergonomic Sports System underwear product packaging is already plastic-free and made from recycled paper. Hooks made of plastic have already been converted to recyclable material.

The balance to be struck for FALKE is ensuring that they can keep their customer happy, continue to make steps to being more sustainable and also trying to keep costs of the production and of the end product down. Looking to the future, by 2024 FALKE is attempting to re-work 60% of the basic and seasonal basic collections to sustainable ground materials, with functional yarns, finishings, dying processes and packagings to be changed in a parallel way where possible. FALKE fully understands that to be more sustainable, the product range must get smaller, will involve less dung and particular styles within the collection will be lost altogether. This may be no bad thing if it encourages the customer to buy better and focus on great quality products that last a long time.

A full version of this feature can be found in The Rakish Gent Issue 4.